Shipping containers are incredibly useful for DIY projects – from pop-up workshops to storage sheds – but moving a 5,000+ pound steel box is no easy feat. This is where shipping container wheel kits come in.

A container wheel kit is a set of wheels and mounting hardware that attaches to a standard ISO shipping container, turning it into a mobile unit. Instead of needing cranes or heavy trucks, a DIYer can reposition a container on-site with relative ease.

Using the right wheel kit can save time and labor, and improve safety by preventing the container from dragging or tipping during moves.

In this post, we’ll explain why you might need a wheel kit, the different types available (bolt-on axles, heavy-duty casters, swivel wheels, etc.), and compare the top options in 2025.

We’ll also provide installation tips and buy links from reliable retailers like Amazon and manufacturer websites, so you can choose the best solution for your container mobility needs.

Why DIYers Need Shipping Container Wheel Kits

What They Are: A shipping container wheel kit typically includes brackets or adapters that attach to the container’s corners (using the standard corner casting openings) and heavy-duty wheels or casters that bear the container’s weight. The result is a container that can roll – effectively turning a stationary conex box into something you can tow or push around (at least over short distances). Some kits use large pneumatic tires (similar to trailer wheels) while others use industrial swivel casters.

Why Use One: DIYers often repurpose containers for storage or building projects, and being able to move the container offers huge convenience. Imagine repositioning your container garage in your yard without hiring a crane, or moving your tiny-home container to access utilities – a wheel kit makes this possible. Wheels also protect the ground and container by rolling instead of scraping, and they add maneuverability for tight spaces. In short, the right kit “helps you move containers faster, safer, and with less effort”. If you plan to frequently relocate a container or adjust its placement on a job site, a wheel kit is a smart investment.

Important: These kits are for off-road and on-site use only. They are not meant to turn a container into a road-legal trailer for highway speeds. Nearly all manufacturers explicitly state “off road use only”. You should move the container at walking speed or with a slow vehicle (e.g. tractor or forklift) on private property. For any significant distance or on public roads, use a proper container trailer.

Types of Shipping Container Wheel Kits

DIYers in 2025 can choose from several types of wheel kits, each suited to different needs. The main categories are bolt-on axle kits, swivel caster kits, and heavy-duty towing dollies. Here’s a breakdown:

1. Bolt-On Axle Wheel Kits (Clip-On)

These popular kits provide a removable axle and wheel assembly that attaches to the container’s bottom corners. They often utilize the container’s ISO corner casting pockets for mounting – you insert the bracket into the corner slot and twist or bolt it in place. For example, the EZY Wheels system (a well-known brand) pioneered this “clip-on axle” design. Bolt-on kits typically come in pairs (for two corners), and you can use one pair on one end of the container (like a trailer axle) or two pairs on all four corners.

- How They Attach: Most use a twist-lock style mechanism or brackets that slot into the corner casting. You rotate the adapter 90° inside the corner to lock it, then secure it with pins or straps. This means no drilling into your container – the kit uses the standardized corners for strength. A ratchet strap is usually added over the top of the wheel bracket to keep it firmly in place during movement.

- Wheels and Capacity: Bolt-on axle kits often use full-size wheels (like trailer tires 14–16 inches) for better rolling over rough ground. Weight capacities are quite high – generally around 8,800 lbs Safe Working Load per set (two wheels). That is enough to move a 20ft or 40ft empty container (typically 5,000–8,000 lbs) and even a lightly loaded one, but not a fully loaded container. In fact, manufacturers clarify these kits are “engineered for handling empty containers and not designed to transport fully laden containers.”

- Pros: Bolt-on axle kits tend to have excellent durability (heavy steel construction) and use pneumatic tires that handle uneven surfaces (dirt, gravel) well. They effectively turn your container into a trailer that can be towed with a vehicle or moved with a forklift at one end. Since the wheels are larger, they roll easily and can support a lot of weight for on-site moves. They’re also removable and reusable on multiple containers.

- Cons: Installing them requires jacking up each container corner (~6-13 inches) to fit the wheel brackets, which can be laborious without the right jack. They do not swivel, so steering a container on four fixed wheels is challenging – often users will put wheels on one end and use a steerable implement (like a hitch on a tractor) on the other end to turn. They are also relatively bulky to store when not in use. Lastly, quality varies; while premium brands (Container Nut’s EZY Wheels) are engineered and certified, cheaper kits exist that may have looser tolerances – always ensure the kit is rated for your container’s weight.

Popular Bolt-On Kits:

- Container Nut “EZY Wheels” (6-Lug and 8-Lug): The original USA-made clip-on axle kit.

Capacity: 8,800 lbs per set (17,600 lbs on four wheels).

Includes steel hub adapters, large 16″ tires, ratchet straps, and even a jack tool (EZY Lift) in some bundles.

Proven design, heavy-duty build (cold-rolled steel, robotic welded) and galvanized finish for weather resistance.

Pros: Extremely robust and trusted (used by military and industry), easy to install with included lift tool, ideal for rough terrain.

Cons: High cost (around $1,200+ for a full kit with wheels), and you’ll need a towing attachment (EZY Hitch, sold separately) if you want to pull the container like a trailer.

Buy: Available via Container Nut’s website and authorized retailers (also found on Amazon as the official EZY Wheels kit).

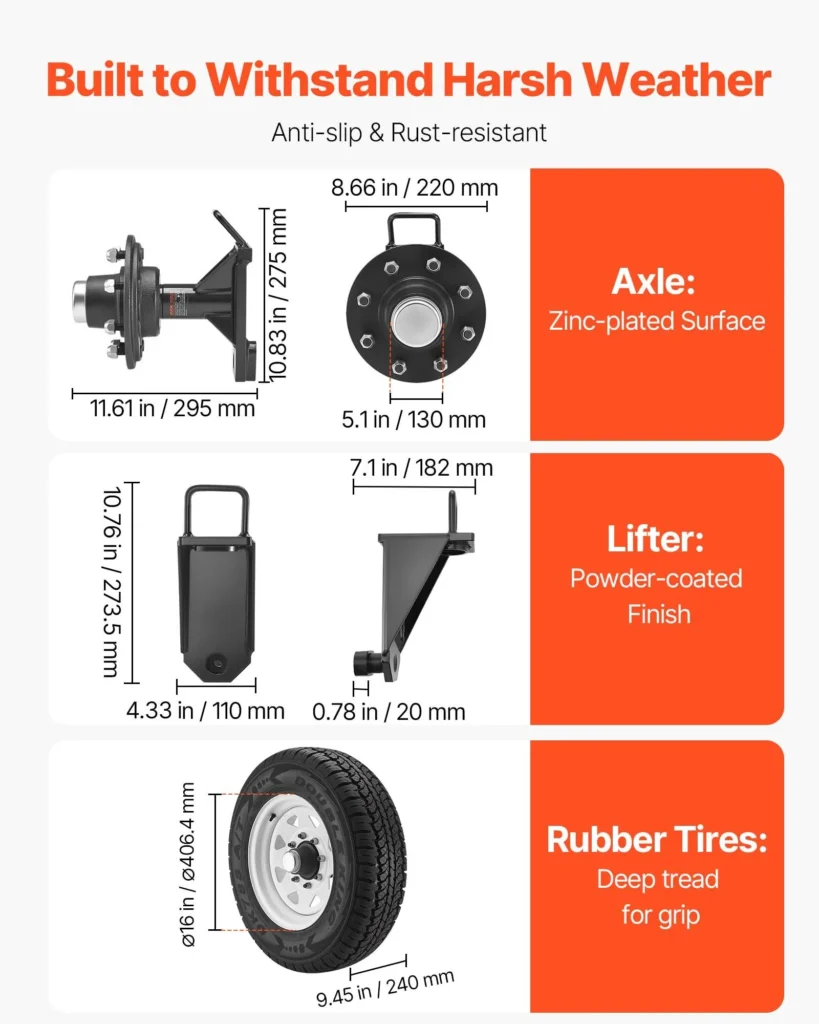

- VEVOR 8-Lug Container Wheel Kit: A popular affordable alternative available on Amazon.

Capacity: ~8,800 lbs per set, similar to EZY Wheels.

This kit comes with two 8-lug hubs, 16-inch rubber tires, and even a small jack and tie-down straps– basically everything needed to get rolling.

Pros: Lower price (~$500-$600 range), includes tires and jack, solid steel build with anti-rust coating. Users report it “easily moves 40 ft empty containers” on firm surfaces.

Cons: The steel quality/fit may not be as refined as premium kits, and the included jack is suitable for empty loads only. Also, some assembly is required (mounting the wheels to the hubs).

Buy: Available on Amazon – look for “VEVOR 8-Lug Shipping Container Wheels Kit”.

- Generic 6-Lug Bolt-On Kits: Several brands (e.g. Fistihon, Dawselod, Onesnt) offer 6-lug wheel kits, often 2-packs.

Capacity: ~8,800 lbs per set (certified).

They usually use a 6×5.5″ bolt pattern hub – compatible with many truck/SUV wheels if you need to supply your own tires.

Pros: Very budget-friendly (around $300-$700 depending on including tires or not), and simpler to handle (a bit lighter weight). Often include shackles and straps for securing the brackets.

Cons: 6-lug kits handle slightly less weight than 8-lug in practice (best for 20ft containers or empty 40ft). They also require you to have or purchase wheels/tires separately in some cases.

Buy: Find these on Amazon (search “Shipping Container 6-lug wheel kit”) or container accessory stores – for example, Onesntshop sells a 2-pack kit online.

2. Swivel Caster Wheel Kits

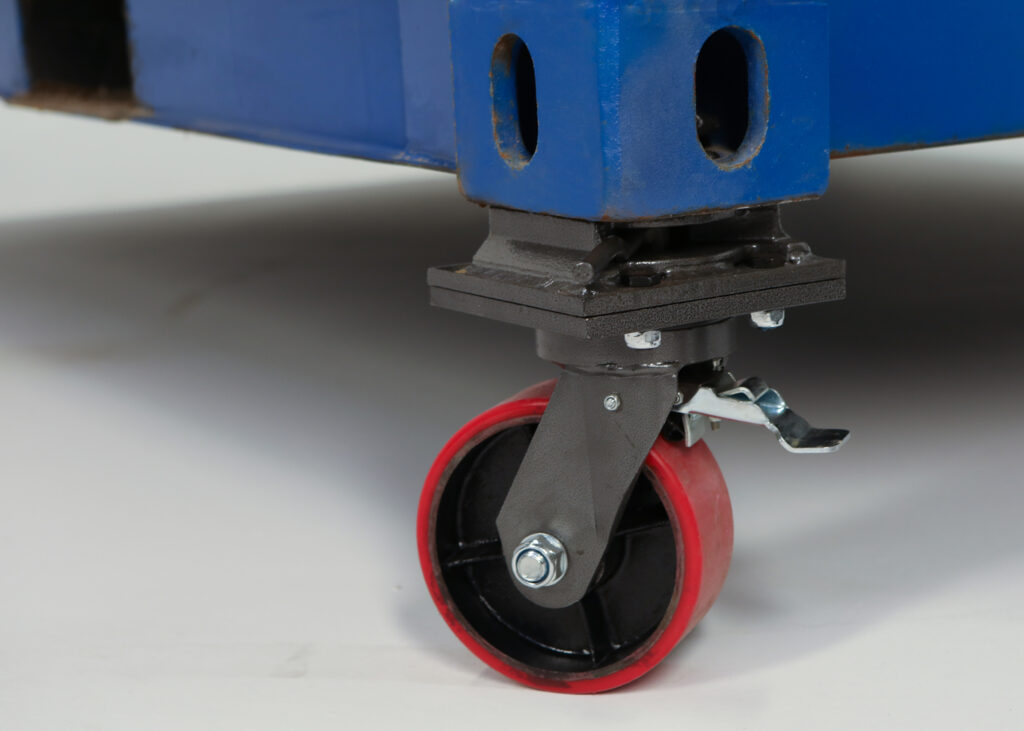

For maximum maneuverability, DIYers can use swivel caster wheels on their containers. These are essentially oversized industrial casters with a twist-lock pin that fits into the container’s corner fitting. Unlike the bolt-on axles, caster kits have 360° rotating wheels (often with a brake), allowing the container to be rolled in any direction or spun in place. This setup is common in warehouses or yards where you might push the container into a precise spot.

- Design & Attachment: Each caster has a post or plate that locks into the ISO corner. Many use a built-in lever or handle to engage the twist-lock into the corner casting for quick installation. You will need to lift the container just enough to get the casters under each corner (typically a jack or forklift at one end, install two casters, then repeat on the other end). Some caster sets include two rigid and two swivel wheels – you’d put the rigid wheels on one end of the container and swivels on the other for easier steering control (this is similar to how a shopping cart or heavy cart is configured).

- Capacity: Swivel container casters are heavy-duty – usually rated around 6,600 lbs per caster for 8″ wheels, and up to ~11,000+ lbs for larger 10″ dual-wheel versions. Using four casters, a typical set might support ~30,000–40,000 lbs total (enough for a partially loaded container). For example, a single 8″ caster from Insta/Stlbx is rated 3 tons (6,600 lbs) and has a brake included. Generally, casters have lower clearance and are intended for smooth surfaces – keep that in mind for capacity if rolling on rough ground (uneven force distribution).

- Pros: The big advantage is maneuverability – you can pivot or side-shift a container easily in a tight space, something not possible with fixed axle wheels. Many caster wheels come with foot brakes so you can lock the container in place once positioned. Swivel casters are also modular; you can use one under each corner or even use just two under one end (though for safety, four is recommended for full mobility). They’re great for warehouse and shop environments where containers need to be moved indoors on concrete. Setup is quick: twist-lock and go, no extra straps needed, and typically no tools beyond the jack to lift initially.

- Cons: Caster kits are usually the most expensive option per wheel. High-quality ISO container casters can run $500+ each, though cheaper imports exist. They are heavy (often 50–60 lbs each), so handling them requires some muscle. Swivel casters with small hard wheels do not perform well on soft or uneven ground – they can sink into dirt or gravel. They truly shine on paved surfaces or concrete. Also, because they swivel, controlling a container on a slope can be tricky – always use the brakes and chock the wheels when needed.

Popular Swivel Caster Kits:

- Stlbx/INSTA 8″ Swivel Caster Wheels: A Canadian-made caster designed for ISO containers.

Specs: 8″ diameter × 3″ wide polyurethane wheel, 6,600 lbs capacity each, with a twist-lock mounting and foot brake. Two or four of these can be used per container.

Pros: High build quality, easy install, comes with brake. Ideal for moving empty or moderately loaded containers on firm surfaces.

Cons: Price is about $550 each (approx. $2,000 for a set of 4).

Buy: Available from Stlbx (Canada) or Insta Container Modifications dealers.

- Mytee Dual Container Casters: Mytee Products offers dual-wheel swivel casters with brakes and twist-locks, each rated up to 11,000 lbs WLL. Four of these can support ~44,000 lbs (nearly 22 tons) – a very heavy-duty option.

Pros: Massive capacity, dual wheels for better weight distribution, and they have locking mechanisms to fix direction if needed.

Cons: Extremely heavy units and costly; overkill for most DIY needs unless you plan to move partially loaded containers routinely.

Buy: Direct from Mytee Products or industrial suppliers (these may not be on Amazon due to their specialized nature).

- Tandemloc & Others: Companies like Tandemloc and Coldene make ISO container caster sets geared toward industrial users.

These often come as sets of 4 (2 swivel, 2 rigid) and boast quick installation and very high capacities (some over 30 tons).

Pros: Great for very heavy loads and frequent use.

Cons: Pricing can be several thousand dollars per set, and likely beyond the scope of casual DIY projects.

Buy: Through specialized material handling suppliers (contact the manufacturer for dealers).

3. Heavy-Duty Container Dollies & End-Wheel Systems

In addition to axles and casters, there are specialized kits for towing or moving containers that don’t fit the above categories neatly. We’ll mention two notable types:

End-Wheel Relocation Kits: These are wheels that attach to one end of the container (usually the rear end) so you can roll the container like a trailer. A prime example is the ContainGo End Wheels system. Two wheels lock onto the end corners without lifting the container (they insert horizontally into the corner casting holes) and effectively put the container on a small axle at the rear. You then lift the front end of the container slightly (e.g. with a forklift or jack) and tow it slowly like a trailer.

Capacity: ContainGo’s wheels have about 5,500 lbs dynamic load per wheel (11,000 lbs per end), sufficient for empty or lightly loaded 20ft containers on flat ground.

Pros: Incredibly fast to install – “in seconds, by hand, no tools needed” – and no need to jack up the container to mount them. Great for quickly unloading a container off a truck or repositioning on a job site.

Cons: Only two wheels, so container must be supported or lifted on the other end during movement; not meant for long distances or uneven terrain.

Buy: Direct from ContainGo (made in USA, sold via quote request).

Heavy-Duty Dollies (Container Skate Trailers): These are essentially mini trailers for containers, with built-in wheels and a tow bar. For instance, Mytee’s Container Dolly and some “skate” systems can handle a fully loaded 40ft container (~70,000 lbs) by using multiple wheels (e.g. a skate assembly with 32 small wheels). These allow a truck to tow a loaded container at slow speed around a yard.

Pros: Only solution for moving fully loaded containers without a standard truck chassis – huge capacity.

Cons: Extremely expensive and usually not practical unless you’re a business (at which point, renting a container chassis might be easier). For most DIY folks, it’s more sensible to empty the container before moving and use one of the above kits.

Now that we’ve covered the types, let’s compare some of the top wheel kits of 2025 side by side, including their key features, pros/cons, and best use cases.

Comparison of Top Container Wheel Kits (2025)

| Wheel Kit & Type | Weight Capacity | Features | Pros | Cons | Ideal Use Case |

|---|---|---|---|---|---|

| EZY Wheels by Container Nut – Bolt-On Axle Kit (6-Lug or 8-Lug) | 8,800 lbs per pair (17,600 lbs on 4 wheels). Off-road only. |

Clip-in axle hubs + 16″ tires; includes jack adapter & straps. Made in USA, steel construction.

Buy from Container Nut — from $737.99

(8-lug kit listed at $796.99)

|

Durable & Proven – engineered for 20ft/40ft containers; large tires roll on rough ground; complete kit (tools included). | High Cost; requires jacking container to install; no swivel (needs wide turn radius or hitch assist). | Regular DIY moves on uneven terrain; farms, construction sites where quality and reliability are paramount. |

| VEVOR 8-Lug Kit – Bolt-On (Budget Option) | ~8,800 lbs per set (two wheels). Suitable for empty 40ft. |

Bolt-on hubs with 16″ rubber tires; comes with small jack and tie-down J-hooks. Powder-coated steel.

Buy on VEVOR US — $681.99

(often discounted on eBay US: ~$229.99)

|

Affordable complete kit; quick leveling and install with included jack; good traction tires. | Slightly lower finish quality; jack is light-duty; not for heavy loads beyond empty container. | Budget DIY projects; occasional moves of empty containers on firm ground (e.g., moving a storage container in a yard). |

| Insta/Stlbx 8″ Caster Wheels – Swivel Casters (set of 4) | 6,600 lbs per caster (26,400 lbs on 4). 8″ diameter wheels. |

Four ISO twist-lock casters (2 swivel+brake, 2 rigid recommended); steel with polyurethane wheels. Each ~64 lbs.

Buy (Stlbx) — CA$545 each

(~US$400 each; ships from Canada)

|

Highly maneuverable (360° rotation) for tight spaces; integrated brakes for safety; tool-free attachment. | Expensive (≈$2k for 4); best on smooth surfaces only; heavy to mount; limited off-road capability (small wheels). | Workshops & Warehouses – ideal for rolling containers on concrete floors, positioning container offices, etc., where precision is needed. |

| ContainGo End Wheels – End-Mount Wheels (Trailer Mode) | 5,500 lbs per wheel dynamic (11,000 lbs per end). 10,000 lbs static per wheel. |

Two large wheels attach to one end via lock pins. Includes two ISO attachment pins. Use with forklift or loader to tow.

Request Quote — ContainGo (US)

(official site; pricing by quote)

|

Fast install (no jacking, mounts in seconds by hand); gentle on surfaces (no dragging); great for straight-line moves and truck loading/offloading. | Only moves container in one direction (no steering except via towing vehicle); not for rough terrain or > slow speeds; for empty/light loads only. | Container relocation on-site – e.g., delivery companies, construction sites using forklift to spot empty containers without a tilt-bed truck. Also handy for aligning containers during prefabrication. |

| Mytee Dual Casters (Heavy-Duty) – Swivel Casters (Industrial) | 11,000 lbs per caster (≈44,000 lbs on 4). 10″ dual wheels. |

Four casters (twin-wheel design) with twist-lock mounting, brakes, and swivel locks. Robust steel and cast/nylon wheels.

Buy 4-Pack (Mytee US) — see price

(single-wheel version listed from $479.99 each)

|

Extreme capacity – can handle partially loaded containers; dual wheels roll smoother under load; directional lock can convert swivel to fixed for towing. | Very heavy and costly (hundreds each); requires equipment to install due to weight; still not intended for high-speed towing. | Industrial use & heavy loads – moving a container with equipment inside within a yard or factory. Overkill for most DIY, but an option if moderate loads must be moved without unloading. |

Installation Tips for Container Wheel Kits

Setting up a container on wheels is a doable DIY task, but it demands caution and the right tools. Here are some practical tips for safe and efficient installation:

1. Empty the Container First: Always unload as much weight as possible from the container before attempting to lift or move it. Even the strongest wheel kits are designed for empty or lightly loaded containers. Never exceed the kit’s rated capacity – if your container is full, rent proper equipment instead.

2. Use Proper Lifting Equipment: To attach bolt-on axles or casters, you’ll need to raise each corner of the container a few inches. A high-capacity bottle jack or hydraulic jack (8–12 ton) works well. Lift one end at a time, placing sturdy blocks or jack stands under the container for safety. Never crawl under a container that’s only supported by a jack – ensure it’s cribbed or blocked before positioning the wheel assemblies. If available, a forklift can lift one side of the container while a helper installs the wheels on that side, then repeat for the other side.

3. Install on Level, Hard Ground: Whether you’re jacking up the container or rolling it on wheels, a flat and solid surface is crucial. Soft soil may cause the jack to sink or the wheels to bog down. For dirt sites, place steel plates or thick plywood under jacks and under the wheels once attached, to distribute weight. Hard surfaces like concrete or asphalt are ideal for using the wheel kits.

4. Secure the Wheels Properly: Follow the kit instructions for locking the wheel brackets in place. For example, with clip-on axle kits, insert the adapter fully into the corner casting and rotate it 90° to lock behind the internal lip. Then attach any safety pin, shackle or strap provided. The strap (often a 2″ ratchet strap) usually goes over the container’s bottom frame and hooks to the wheel bracket, preventing the bracket from dislodging or “jumping” if the container hits a bump. Swivel casters typically have a locking lever – make sure it’s engaged in the corner casting. Double-check each wheel to ensure it’s secure before attempting to move.

5. Move Slowly and Steadily: With the wheels on, remember that a container is still a very heavy object with a high center of gravity. If pulling with a vehicle, go slow (walking speed) and avoid any sudden turns or stops. For casters, you might push the container manually using leverage (e.g. pry bar) or a vehicle/puller. Keep the path clear of obstacles and have a spotter if possible. Avoid slopes – even with brakes, a heavy container can overwhelm them. If you must go down a slight grade, do so with extreme caution, and never let anyone stand downhill of a moving container.

6. Braking and Chocking: Most swivel caster kits have built-in foot brakes – engage these whenever you stop, to prevent rolling. With axle-style kits, bring wooden chocks or wedges to block the wheels once you’ve moved the container to the desired spot. Additionally, use the provided ratchet strap or an extra tie-down to anchor the container to a fixed object if it will remain on wheels for some time. For long-term placement, it’s recommended to remove the wheels and set the container back on firm supports (e.g. railroad ties or concrete pads) for stability.

7. Practice Safety: Work with a friend if possible – one can operate the jack or vehicle while the other monitors alignment and signals. Wear steel-toe boots and gloves when handling these heavy metal components. If any wheel assembly looks misaligned or is binding, stop and fix it rather than forcing movement. Periodically check that all attachment points are holding tight, especially if moving over uneven ground which can cause vibration.

By following these tips, even a solo DIYer can safely get a container on wheels and relocate it as needed. Take your time and respect the weight involved.

Conclusion

In 2025, there are more options than ever to make your shipping container mobile. Whether you need a simple bolt-on wheel kit to drag an empty storage container around your farm, or heavy-duty swiveling casters to glide a container workshop in your warehouse, the right solution is out there. We’ve covered bolt-on axle kits (great for rough terrain and straightforward towing), swivel caster kits (best for precision moves on smooth surfaces), and specialty systems for heavy loads or quick attachment. Each has its pros and cons, but all share a common benefit: they turn a once-immovable steel box into a versatile, moveable asset.

For most DIY enthusiasts, a mid-range bolt-on kit or a pair of container casters will do the job of moving an empty 20ft or 40ft container with ease. Just be sure to mind the weight limits, and follow proper installation and safety practices. As the products we’ve highlighted show, these kits are engineered to handle the task – for example, the top brands are “engineered for industrial use” and have been tested to safely move standard containers. With a bit of planning and the right gear, you won’t need to call in a crane just to rearrange your container project.

We hope this guide has helped you understand the best shipping container wheel kits available in 2025. Now you can confidently choose the kit type that fits your needs and budget. Before you know it, you’ll be rolling your container into its perfect position for your next DIY venture. Happy container moving!

Read Also:

This $5.2M Shipping Container Mansion Redefines Luxury Living in New Hampshire

How to Insulate a Shipping Container Home (Without Wasting Money)

A Deep Dive: Engineering Challenges and Solutions in Shipping Container Home Construction

Is Container Home Right for Me? Key Considerations Before You Decide

Be First to Comment